Coal Flotation Machine

StackCell™ Flotation – A New Technology for Fine Coal Recovery

StackCell™ Flotation – A New Technology for Fine Coal Recovery Michael Kiser, Robert Bratton and Gerald Luttrell Mining Minerals Engineering, Virginia Tech, Blacksburg, Virginia USA Jaisen Kohmuench, Eric Yan and Lance Christodoulou Eriez Manufacturing, Erie, Pennsylvania USA Van Davis and Fred Stanley Alpha Natural Resources, Bristol, Virginia USA ABTRACT During the past decade, .

WASHABILITY AND FROTH FLOTATION TESTS OF LAFIAOBI COAL

Froth flotation at Ph7 of the coal gave an average ash content of the total float to be % with the higher ash content reporting in the first float %. The sulphur, moisture and volatile matter are same as in the raw coal. Froth flotation at Ph9 of the coal gave an average ash content % with the fine coal reporting first with less ash content of %. This difference could ...

USA

The froth flotation of coal is conducted in the presence of a conditioner of an oxygen containing compound of the formula: ). (I) wherein R 1 and each R 2 are independently saturated hydrocarbyls and n is from 1 to about 3.

SUEK cleans up with new flotation unit at Kirov coal ...

· SUEK says it has commissioned a new flotation unit at the Kirov coal wash plant in the Kemerovo region of Russia. The technology, introduced at SUEK for the first time, maximises washing efficiency of coal fines ( mm), producing a highquality concentrate (calorific value over 6,600 kcal) with an ash content of 89% from a product containing 3040% ash, the company explained.

News | allmineral Aufbereitungstechnik GmbH Co. KG

· Whether polymetallic ore flotation, coal or platinum minerals: The optimised flotation process puts you ahead within the industry. With breakthrough advances compared to mechanical agitator flotation, the allflot® puts you on course for victory, both technically and economically. The advantages of the flotation system for your operations such as: Unique flexibility thanks to a new, .

Top Brand Latest Designed Flotation Machine For Coal ...

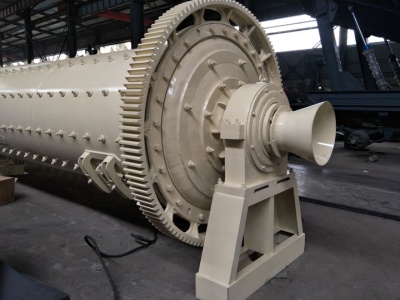

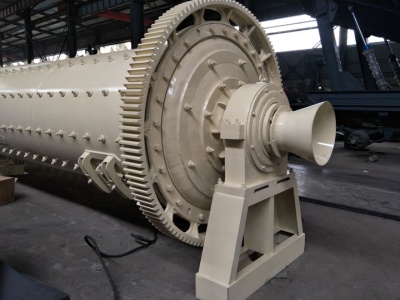

Read More Coal crusher. Coal crusher is one kind of crushing equipment used for crushing lump coal into small size, so its also known as coal crusher machine, coal crushing equipment. Read More Ball Mill. Ball mill is also known as ball grinding mill. Get Price; Used Mobile Cone Flotation Process In Delhi Conzio. mobile gyratory flotation ...

DEASHING AND DESULPHURIZATION OF FINE OXIDIZED COAL BY ...

Flotation tests were conducted for the separation of fine oxidized coal. Flotation machine models and operating parameters were mentioned in section In those tests, different frother dosages and collector dosages were tested to optimize the separation efficiency of flotation. Clean coals and tailings were obtained after each experiment. Enhanced gravity separation tests Falcon centrifugal ...

FLSmidth's flotation REFLUX™ revolution

· Beyond this, we can also offload overloaded coal flotation circuits as the RFC is a high capacity machine with a small footprint." Reference: Cole,, Dickinson,, and Galvin,, Recovery and Cleaning of Fine Hydrophobic Particles using the Reflux TM Flotation Cell, Separation and Purifiion Technology, 240 116641 (10 pages) 2020. While coal has historically been the initial ...

Salient features of PNEUFLOT®:

This innovative and exceptionally efficient machine is the propriety item of MBE which ers to the flotation process required to enrich lean grade ores and coking coal thus ensuring maximum recovery of the depleting resources. The PNEUFLOT® cells are characterized from other flotation machines present in the market by its self aeration technology (no need of blower) and absence of any ...

Efficient Stone Coal Flotation Machine Price

Efficient Stone Coal Flotation Machine Price. 2 coal slurry smiles dehydration process after flotation nowadays highefficiency dehydration equipment such as pressure filters and diaphragm squeeze filter are increasingly used for dewatering of flotation clean coal especially now the design of coking coal preparation process adopts the principle of grade separation for coal slime.

Cleaning Equipment|Slu my Water Treatment Equipment|Dy ...

Tangshan JinZe Machinery Manufacturing Co., Ltd (Shortened to TJ MMC or Tangshan Jianhua) is a technology and innovationbased enterprise with coal cleaning project design and RD and manufacture of coal cleaning equipment as its main business line, The company has long been dedied to the development and innovation work in coal preparation sphere, in line with the principle of ...

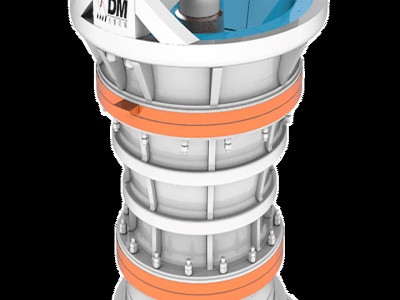

Column Flotation

coal. Flotation columns differ dramatically from mechanical flotation machines in . several ways: • there is no mechanical agitation/shear • the cell is relatively tall and narrow • gas bubbles are generated by sparging • froths typically are deeper, and wash water typically is liberally applied to the surface of the froth. There has been a wealth of research and fundamental studies on ...

coal industry flotation processing machine

coal flotation machine flotation machines the coal industry uses either mechanical or column cells mechanical the most commonly used sotation machine is one in which a, flotation coal processing system machine for sale find the right and the top froth flotation flow chart for your coal handling plant! pneuflot® Get Price . gold mine processing flotation machine with 17 ...

Extending the upper particle size limit for coal flotation

using a Denver D12 flotation machine. In each test, a 250g coal sample was used in a 4litre stainless steel flotation cell. Sufficient makeup water was added in each test to maintain a pulp level approximately cm below the froth overflow lip. The coal sample was conditioned in the flotation cell at 1,500 rpm for min after adding a known dosage of reagent. After the conditioning, 150 ...

FLOTATION OF LONG FLAME COAL PRETREATED

flotation of fine long flame coal. The flotation recovery of long flame coal could be increased when long flame coal was either pretreated or conditioned with Tween 60 in a flotation cell for a period before the addition of collector. Fourier Transform Infrared (FTIR) technique was used to indie surface properties of long flame coal. The results of FTIR show that there are many oxygen ...

XFD12 Mechanical Cell Flotation

XFD12 Lab Multicell Flotation Machine is an experimental standard flotation machine for coal dressing and is also suitable to apply in metallurgical, geological, coal, building material, chemical, environmental protection and other industries for agitating, scrubbing, separating and cleaning minor samples. The speed of the impeller can be adjusted stepless and the speed can be displayed ...

The Best Coal Industrial Rock ...

The flotation machine is driven by Vbelt drive motor rotating impeller to create negative pressure by centrifugal vacuum. The flotation cell is a very important part of the flotation machine. Rotary Kiln. Rotary kiln is mainly used in the industrial field, such as mineral processing plants, cement plants, garbage disposal plants, lime production and so on, so it's also called rotary cement ...

Flotation froth recognition system based on machine vision

· Coal flotation mainly uses the difference between the surface hydrophilicity and hydrophobicity of coal particles, caused by their interaction with reagents, which results in the separation of clean and tail coal from coal slime in the flotation machine or flotation column [1, 2]. In the flotation process, the reagent dosage is the main factor affecting a stable operation and the quality of ...

Latest Posts

- معدات غسل الرمل في جنوب أفريقيا

- مخطط تدفق الذهب محطم

- مشاركة مطحنة سيتون اندونيسيا

- تكلفة ساعة VSI كسارة الحجر

- الكوارتز طحن الكرة

- صغيرة الحجم الكلي سحق النبات

- سعر الاسمنت

- كوماتسو BR محطم للبيع في الهند

- سحق وتجفيف الجدران أو ألواح الجبس

- التايلاندية مصنع طحن الباريت

- تهتز الشاشة مخروط محطم

- حزام ناقل مع مقياس هوبر

- ماليزيا محطم سعر التشغيل

- هذا هو طحن المعادن

- Construction Grade Sand From Glass

- Copper Ore Ultrafine Grinding Mill

- Equipment Used In Rare Earth Elements

- Stone Crusher Croatia

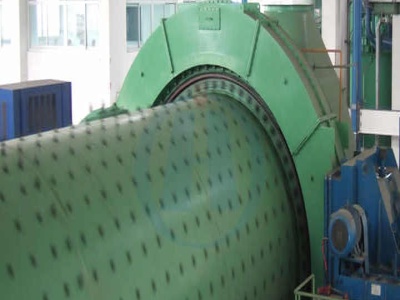

- Ball Mill For Sale Ball Mill For Sale Products Ball Mill

- Raymond Mill Works

- Grinding Stone Type Wa Gc1500k

- Cornejo Materials Cornejo Quality Stone Cornejo Sons

- Allis Chalmers Rock Crusher Repair Parts

- Industryies Mills For Sale

- For Sale Turbo Concrete Fllor Grinder In The Philippines With Price

- Crusher Benih Stone

- Grinding Machine Price In Sri Lanka In Badulla

- Conveyor To Conveyor Interlock Switch

- Crushing Screening Por Le

- Cone Socket And Eccentric Clearances