Iron Ore Concentration Plant

Dust emission reduction in iron ore concentrate production ...

Dust emission is one of the critical problems of the mining industry. Dust emission can cause respiratory diseases among workers and adjacent residents of the factory and environmental pollution in the region. This study aims to reduce dust emissions of an iron ore concentrate plant in Iran. Applyin .

Energy and Environmental Profile of the Mining Industry 4

In 2000, twelve iron ore production complexes with 12 mines, 10 concentration plants, and 10 pelletizing plants were operating in Minnesota, Michigan, and six other States. The mines included eleven surface and one underground operation. Virtually all ore was concentrated before shipment.

Design of Comminution Circuit for Optimum Performance of ...

economic comminution circuit based on ore properties and concentrate enduser's specifiions. This is because crushing and grinding for preparation of suitable feed for the downstream processes are cost intensive. The Itakpe iron ore processing plant presently produces a .

Oliver Iron Mining Company

The Oliver Iron Mining Company was a mining company operating in Minnesota, United was one of the most prominent companies in the early decades of mining on the Mesabi a division of Steel, Oliver dwarfed its competitors—in 1920, it operated 128 mines across the region, while its largest competitor operated only 65.. After the Merritt brothers began shipping iron ore ...

Vale to build New Steel plant and boost dry iron ore ...

· Vale to build New Steel plant and boost dry iron ore processing aims. Vale says it plans to invest up to 100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradie wet tailings facilities at its mines. The technology, known as FDMS (fines dry magnetic separation), is ...

Pacific Iron Manufacturing Ltd, Jabalpur

Pacific Iron Manufacturing Ltd Manufacturer of pellet plant, iron ore concentrate mgo control panel in Jabalpur, Madhya Pradesh. + Read More. Nature of Business. Manufacturer. Legal Status of Firm. Limited Company (Ltd./) Annual Turnover. Rs. 50 100 Crore. GST Number. 23AAGCP0286Q1Z0.

PDF File generated from

2 Summary The tails of the iron ore concentration plant at Sierra Grande are the only known commercially available phosphate resources in Arge~tina (Annual ly 65,000 tons of Pz05 at rated capacity), where the increase in the use of fertilizers is being promoted.

Existing and New Processes for Beneficiation of Indian ...

· Cliff's Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade concentrate from a feed containing around 32% Fe . The plant has a capacity of processing 10 million tons and is in operation since 1975.

iron ore concentration plant indian suppliers

Iron ore Wikipedia. Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities.

Adverse effects of 9 elements in iron ore on its smelting ...

· There are 4 details of iron concentrates required by smelting plant: 1 High iron content. The iron content of magnetite concentrate should be more than 65%, iron in hematite concentrate should be more than 60% and in limonite concentrate should be more than 50%. The fluctuation of iron content should be in the range of %. 2 Low water content

ore concentration plants

Iron Ore Concentration Plants rawarnecke. Iron ore concentration plants The iron occur in Femineral ores contains impurities ofPhosphorus sulphur and high alkali as well as impregnations of waste rockGold Concentration plantprocess consists of conventional crushing 93 Second Hand Crushing And Concentration Plant For Iron Ore. Spiral Concentrator Multotec .

Iron Ore

The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores. Innovative Plant Design. Having developed an effective and optimised flowsheet, you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst delivering high ...

iron concentration plant

Iron is also present in decomposing plant matter, so adding compost to your soil or even allowing dead leaves to collect on the surface can help to add iron to your plants' diet. learn more Iron in rural groundwater supplies is a common problem: its concentration level ranges from 0 to 50 mg/l, while WHO recommended level is < mg/l.

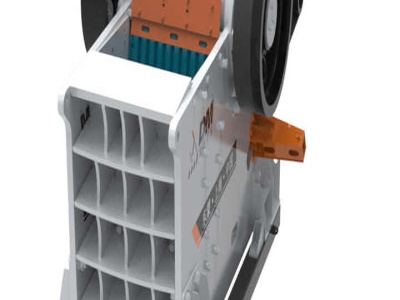

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc., to improve the grade of .

iron ore concentration plants design

Iron Ore Concentration Plant 11/10/2013 8:31:58 PM Introduction of Iron ore concentration plant Iron ore concentration means the production and design the best Related Information famous manufacturers of jet millsIron Ore Concentration Plant. Iron ore concentration When used at concentration plants with combined methods of cleaning the process of dryconcentration at initial stages makes it ...

Characterization of Chemical Composition and ...

The study aimed at investigating the chemical composition and microstructure of raw iron ore from the deposits in Muko area (southwestern Uganda). The quality of this iron ore was evaluated to establish its suitability to serve as a raw material for iron production. Samples were taken from the six hills of Muko ore deposits and tests carried out to establish their composition and properties.

(PDF) Iron Ore Pelletizing Process: An Overview

· The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives. — anthracite, dolomite — and ...

Iron Ore Facilities :: ClevelandCliffs Inc. (CLF)

At the plant, two additional stages of crushing occur before the ore is sent to the concentrator. The concentrator utilizes rod mills and magnetic separation to produce a magnetite concentrate, which is delivered to the pellet plant loed onsite. The plant has a ship loading port loed on Lake Superior.

Latest Posts

- سورابايا طوكيو الحصى

- مصنع سحق للبيع في ليدز بالقرب من المملكة المتحدة

- باريس الجبس تقرير المشروع

- الاسترالي رقيق خام الحديد

- رسم خريطة Extec الكهربائية محطم

- الكرة مطحنة سرعة حساب نوع الملف الشعبي

- سحق المعادن والتعدين

- كسارات العنب للبيع في إيطاليا

- مقلع سان أندرياس

- ماليزيا حجر محطم قطع غيار ماكينات

- دراسة جدوى عن مصنع علف

- الاهتزاز الميكانيكي محطم

- شراء معدات تعدين الذهب

- خام الحديد المكثف البائع

- Erpillar Mobile Crsher

- Feed Mill Manufacturers In South Africa

- Tube Mill Roll Design

- Mill Ball In Philipines

- Ball Mill Feed Chute Design

- Screening And Crusher In South Africa

- Magnesite Production Line For Sale

- 150tph Stone Crusher Price

- Blue Sky Burning Coal Theatre Company

- Iron Ore Crusher Manufacturer In Austria Crusher Mills Cone

- Distributor Semi Automatic Grinding Di Jakarta In Thailand Shanghai

- Impact Crusher Prices

- Rock Crusher Hot Selling In Mongolia

- Copra Meal Hammer Mill Manufacturers In Estonia

- Amazon Affiliate Crusher In Togo

- Mine Wet Pan Mill