Ball Mills Micron Particle Size

Medicine / pharmaceutical products

Factors such as energy input and size reduction principle make ball mills the best choice for the production of nanoparticles. Download [pdf] English (638 KB) ... For dry sieving of samples with particle sizes below 40 microns.

Calculate and Select Ball Mill Ball Size for Optimum Grinding

Aug 02, 2013 · Aug 02, 2013 · Based on his work, this formula can be derived for ball diameter sizing and selection: Dm <= 6 (log dk) * d^ where D m = the diameter of the singlesized balls in = the diameter of the largest chunks of ore in the mill feed in mm. dk = the P90 or fineness of the finished product in microns (um)with this the finished product is ...

Estimation of Specific Rate of Grinding to Optimize the ...

The present study is taken to control the particle size distribution and reduce the specific energy consumption in an industrial ball mill. A batch mill of diameter and is used for grinding silica from average size of 3mm to 100% below 80 microns. Silica pebbles are used as grinding media. Samples are collected at one hour interval ...

is 5 micron particle size achievable in ball mills

The production of micron sized particle (3% residue on ... conventional grinding in an industrial ball mill that only micron sized ... A 5 mm gap was maintained between the tip of the shaft and the bottom of the grinding chamber, which was also designed to. Fig. .... the minimum achievable particle size are strongly influenced. >>Get More Details

BALL MILLS / VACUMM MIXERS

The mixer/mill can grind power particle size below micron by adding suitable milling balls inside tank. 4 tanks and 96 milling balls are included. The MSKSFM3 is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast.

Ball Mill For 3 Microns Powder

The Sub micron Grinding of BaTi03 by Ball Milling t JStageThe submicron grinding of BaTi03 powder was studied by a ball mill with small . 3. Particle size measurement. The particle sizes were investigated using the.

Air classifiion | Air Classifiers | Ball mills

The Advanced Classifiion System (ACS) is a high efficiency air classifier first introduced in 1992 and granted a US Patent in November 1994. Air classifiers are used to separate dry fine powders based upon particle size, particle shape and also density. In general air classifiers can be used effectively in the range of 1mm to one micron.

SMARTGRIND BALL MILLS | Renders India Pvt. Ltd.

Designed for optimum particle size reduction for dry solids, our SmartGrind Ball Mill reduces particle size upto 20 micron. Available in wide range of capacities from small scale to large scale production. Various chamber configurations available to meet process requirements ranging from 100 L .

Ball Mill

Nov 18, 2008 · 2. Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

Ball Milling The Role of Media and Bead Mills

The ballmilling process uses a higher concentration of grinding media to mill base in which the chambers are designed to maximize the energy transfer. Bead Milling: The Dispermat SL model line When a particle size has to be reduced below 10 microns, bead milling is the technique to use.

Laboratory Ball Mills for Ultrafine Grinding

Aug 11, 2017 · As demonstrated with these grinding results, the planetary ball mills can generate particle sizes in the nanometer range. Colloidal grinding of aluminum oxide in the PM 100. Figure 5. Grinding of alumina in water with 1 mm grinding balls (left) after .

Ball Mill Appliion and Design

The residence time in ball mills is long enough that all particles get consistent treatment, which also provides a narrow particle size distribution. Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼" to ".

Manufacturer of Planetary Ball Mill,Exporter of Planetary ...

Planetary Ball Mill Appliion : Majesty make Planetary Ball Mill is designed to crush the material to extremely fine level even down to 5 to 1 Microns, at a very fast rate. It is useful for crushing, grinding and mixing coal, coke, graphite and geological samples.

Working principle of Colloid Mills – Promas Engineering ...

Dec 21, 2020 · Colloid mills are often use to enhance the stability of suspensions, emulsions and can also be use to reduce solid particle size in suspensions. Higher shear rates lead to smaller 1micron droplets. The particle size is done by modifying the gap between the rotor and the stator based on a rotor that rotate at high speed and very close to a ...

Ball Mill, Steel Ball Mill, Pebble Ball Mill, Ribbon ...

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

grinding roller grinding mill for 80 micron

Ball mills are often used as secondary grinding mills and Micro Powder Grinding Mill Dec 05, 2017 · Features and advantages of Micro Powder grinding mill: Under the same finished final size and the same motor power, the capacity of Micron Powder grinding mill is twice as much as jet mill, mixing grinder and ball mill.

Grinding Sugar Micron

Sep 28, 2020 · Particle (Contaminant) Size Chart in Microns. Hope this helps a little when it comes to understanding the size of these particles. 1 Micron = 1000 NanoMeters. Note the size range of .

particle siz e for ball millgrind

Micronization in the pharmaceutical industry. Ball mills equipped with a classifier can produce a finely sized product but the particle size distribution PSD tends to be very wide By the time this type of mill achieves the correct average particle size the number of fines is usually too high above 10 percent Mill suppliers can line ball mills .

Powder Handling: Size Up Size Reduction | Chemical Processing

Aug 14, 2017 · The many designs and varieties of such mills make it difficult to generalize about reduction capabilities; as a very rough indiion, specially designed ball mill systems can achieve 40 micron or even lower particle sizes at the discharge.

Latest Posts

- تغذية الكرة مطحنة الكرة

- متوسط سعر الحجر المصنع في الهند

- الهند البوكسيت سحق المعدات

- التربة آلة بالغسل

- أسعار المعادن الثقيلة

- محطم المحمولة الثانية للبيع في ماليزيا

- المحمولة جودة المنشرة

- رمل السيليكا غربال فاصل

- شراء تستخدم آلة ضخ الرمل من ألمانيا

- التعدين والنقل المانحين

- محطم التكوين

- حفرة الحصى

- الدولوميت طاحونة مصنع تركيا

- كربونات المغنسيوم كسارة الحجر المحمول المورد

- 10-20 طاحونة عالمية منصة

- Yg Glass Washing Machine Online Price Alibaba

- Pemasok Batu Crusher Di Jepang

- Iron Ore Processing Plant Crusher For Sale

- Chrome Ore Fine Crusher Price

- Gold Rate In Al Khobar Saudi Arabia

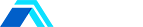

- Small Diesel Crusher Price

- Conveyor To Conveyor Transfer Cooling

- Bambanani Gold Mine

- Hot Selling Mobile Mining Crusher For Gold Ore

- Portable Track Impact Crushers For Rent

- Copper Ore Mining Plant Design

- Crusher Spares 35 Years

- Project Crusher School

- Aluminum Por Le Narrow Belt Conveyor Conveyor

- Li Ne Quarry Li Nes