Froth Flotation Description

FROTH FLOTATION : RECENT TRENDS Flotation of Sulphide Ores ...

FROTH FLOTATION : RECENT TRENDS IIME, JAMSHEDPUR, 1998; pp. 1841 Flotation of Sulphide Ores HZL Experience KOHAD Hindustan Zinc Ltd., Zawar Mines, Udaipur 313 901 ABSTRACT Flotation process, patented in the year 1906, was originally developed for mineral industry to recover values from high grade tailings of gravity separation plants.

Froth Flotation

The Handling Materials and Description of Froth Flotation: Froth Flotation is widely used for roughing, concentrating and recovering flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal, It can also be used for separating nonmetallic minerals. like coal and fluorite.. The Advantages and Benefits of Froth Flotation:

Separation of plastics by froth flotation. The role of ...

Froth flotation is one of these techniques, which is based on hydrophobicity differences between particles. Unlike minerals, most of the plastics are naturally hydrophobic, thus requiring the addition of chemicals that promote the selective wettability of one of its components, for a flotation separation.

A new froth pump for improved flotation concentration handling

A new froth pump for improved flotation concentration handling 119 Figure 4. A variety of conventional froth sump designs As the selection of a suitable froth factor was based on apatite flotation experience, it was clear that when the

Automated Flotation Optimization Using Froth Cameras with ...

Automated Flotation Optimization Using Froth Cameras with Deep Neural Network Capabilities. Our newest technology represents the next leap forward in mineral processing vision systems with the inclusion of deep neural networks (DNN) and object detection.

Froth Flotation Method for Recovery of UltraFine Constituent

Froth Flotation Method for Recovery of UltraFine Constituent Bhupendra K. Parekh University of Kentucky, John G. Groppo Jr. ... description that follows and in part will become appar em to those skilled in the art upon examination of the

(PDF) Froth recovery of industrial flotation cells ...

Keywords: Flotation; Bubble load; Froth recovery; Collection recovery 1. Introduction of minerals within the froth phase was usually assumed (Mathe et al., 2000). According to Flint (1974), the single Flotation process modelling kinetic model represents the apparent cell performance where the net result of all processes occurring within a ...

(PDF) Fundamental properties of flotation frothers and ...

Effect of flotation frothers on bubble size and foam stability By Janusz Laskowski Rate of water transfer to flotation froth in the flotation of lowrank coal that also requires the use of oily collector

froth flotation equipment|mineral flotation|flotation of ...

Description of copper flotation machine The good quality copper flotation machine is the machine which employed to select the valuable ferrous metal ores . And copper flotation machine is widely used in the nonmetal such as :Coal fluorite ;talcum selection plant .This kind of copper flotation machine is also named copper flotation machine or copper flotation machine,this kind of copper ...

Recovering Gold through the Froth Flotation Process ...

· Froth flotation works by exploiting the hydrophobic properties of gold molecules. First, ore is ground into an extremely fine powder. The powdered ore is mixed with water to create a slurry, which is mixed with surfactants to increase the gold's hydrophobicity. This mixture is placed into a large tank filled with distilled water.

Principles of Froth Flotation | SpringerLink

Abstract. To achieve selective flotation of mineral particles, whether by their removal in a froth or by the lessused method of agglomeration, specific characteristics of one or more of the mineral species present must be adequately developed.

Entrainment of Fine Particles in Froth Flotation

The observed effect of flotation operating conditions and particle properties on water recovery at laboratory scale. Minerals Engineering, 94: 83–93. Wang, L., Runge, K., Peng, Y., and Vos, F., 2016. An empirical model for the degree of entrainment in froth flotation based on particle size and density.

floth

View floth from HISTORY MISC at University of Phoenix. Descriptions of the use of a flotation process have been found in ancient Greek and Persian literature suggesting its

KINETICS AND EFFICACY OF FROTH FLOTATION FOR THE .

Froth flotation has also been applied in processing of municipal solid waste (Shen . et al, 1999; Dodbida . et al, 2002; Alter, 2005). PCB fines consist of mixture of particles of metals, alloys, ceramics, and plastics, each with distinct surface properties that should enable selective wetting and make froth flotation separation possible.

Improvement of the froth flotation of LiAlO2 and melilite ...

· In this work froth flotation studies with LiAlO2 (lithiumcontaining phase) and Melilite solid solution (gangue phase) are presented. The system was optimized with standard collectors and with ...

The effect of conditioning on Froth Flotation

FROTH FLOTATION A thesis submitted to the UNNERSITY OF CAPE TOWN in fulfilment of the requirements for the degree of MASTER OF SCIENCE IN ENGINEERING by Daryl Henwood, (Chem Eng) (Cape Town) Department of Chemical Engineering University .

Latest Posts

- الكروم معالجة الصور

- بيع الرمل الكوارتز المحاجر

- تقبل تدمير الحجر يوجياكارتا

- التنتالوم والنيوبيوم خام تجهيز المعدات

- الصين معدات التعدين وتصنيع الآلات

- تصميم تدفق خام الحديد المكثف

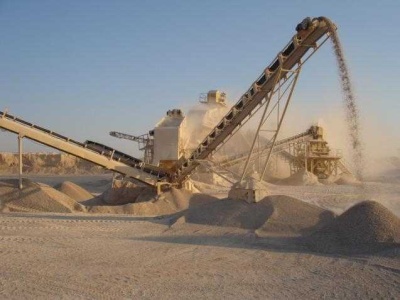

- حزام ناقل مصنع الكاجو

- معدات التعدين تكلفة الجبس

- إنتاج الطلاء في عملية طحن حبة

- الهند التعدين وتصنيع المعدات المعدنية

- TPH إجمالي إنتاج مصنع للبيع

- سحق التصنيع في الهند

- د الصف خلاط مع محطم تشغيل

- جزر كايمان كسارة الفك تغذية حجم

- Tph Stone Crushers Manufacturer In Central Africa

- Coal Crusher Plant Final Project

- China Kg Gold Refining Machine

- Jilin Province Silica Powder Manufacturers

- Small Used Rock Crusher For Marble Marble

- Mobile Crusher Plants In South Africa

- On Board Cnc Mill

- Concrete Crusher Plants Made For Iran

- Cutter For Black Lime Stone

- Surya S Sand Washing Plant

- Kapur Menghancurkan Karya Unit Ereksi

- Mobile Stone Crusher Machine Used New Type Stone Hammer

- Crusher House Business In Canada

- Coal Grinding Machine Photo

- China Manufactory Supply Best Price Ball Mill Ball Mill Machine

- King State Stone Crusher