Schematic Of A Ball Or Rod Mill

There are three sets of instruction sheets here in this ...

A pepper mill is an e xcellent project for turners and carvers alike. Made by America's oldest pepper mill manufacturer, these highquality pepper mill mechanism kits have all the internal components necessary to produce a topload, adjustable grind (coarse through fine) pepper mill. Made of tempered stainless steel with an aluminum shaft. Kits

schematic for small ball milling device for grinding

schematic for small ball milling device for grinding; ... Ball MillRod Mill Grinding System Used in Mineral Milling ... Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries. It can carry out dry or wet pulverizing and can meet demand for ...

CHOOSING USING A MILLING MACHINE

09/03/2019 · 4. A mill spindle is designed for both down load (axial, like a drill press), and also side load (radial). That is why a mill spindle runs in tapered roller bearings (or deepgroove ball bearings) inside the quill. 5. The spindle isn't just for drill chucks — use any R8 compatible device — end mill holders, collets, slitting saws, etc. 6.

Balle Mills Testing

work index series (ball mill, rod mill, and. MacPherson autogenous) and pilot plant tests require relatively more weight (for a given top size) because they are run. Obtenir le prix Get brochure Laarmann

Hammer Mill Schematic Diagram

schematic diagram of ball mill | worldcrushers. schematic diagram of ball mill. As a professional crushing and grinding equipments manufacturer, schematic diagrams for dry ball milling circuits Coal . Raymond Mill Schematic Air Flow Diagram About raymond mill schematic air flow diagramrelated information:process flow diagram for rock crusher ...

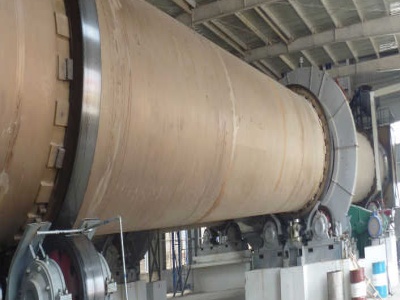

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL | .

The results with the broad bean 13 % moisture content with feed rate of (, and )kg/min, the crushing f490 DESIGN AND EVALUATE OF A SMALL HAMMER MILL efficiency were (%, % and %)respectively. Meanwhile, the losses were (%, % and %) respectively. The difference between results was due to the mechanical ...

Particle technology lab report

PARTICLE TECHNOLOGY LAB REPORT 33 Procedure of Ball Mill Measure the inside diameter of the ball mill. Measure the size of the ball with the help of venire calipers. Fill the ball mill to about half of its volume with balls of the same diameter. Feed t ball mill with 250 g mass of sugar of homogenous size (obtained by screening) and note the ...

ball milling schematics

ball milling schematics pochirajuco. ball milling schematics TECHNICAL NOTES 8 GRINDING R P King Mineral Technologies Reference Manual, Rexnord Process Machinery Division, Rod and ball mills in Mular AL and Bhappu R B Editors Mineral Processing Plant Design Get Price Patent US Control system and method for a reversed ball

Vertical Milling Machine

milling, Conventional or Up Milling (Fig. 1) and Climb or Down Milling (Fig. 2). The figures on the left show the rotation of the cutting tool with respect to the direction of the part on the table. In conventional milling the work is fed against the cutter, which compensates for backlash in the table.

schematic of a ball or rod mill

(9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass. The rod mill discharge is pumped, without any further water addition, to the first ball mill. The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cylcone 1). See Figure 1 for a schematic of the process flow.

Alumina Technology (CETI Enterprises)

15/07/2020 · Ball mill or Rod mill or SAG or combination of any two is generally used in Alumina refineries for the purpose. The particle size of ground bauxite is decided based on the laboratory test work ranging from 149 microns to 1000 microns, however, minus 10 mesh size (100%) has been f ound to be optimum size in most of the operative Alumina ...

MF2048 Hammermills and Roller Mills

Mills in which the rotor speed is approximately 1,800 rpm, hammers should be about 10 inches (≈ 25 cm) long, inches (≈ cm) across, and inches (≈ Screen Takeaway Rotor Rod Delivery device Hammers Figure 1. Corn Kernel Figure 2. Hammermill Hull Horny Endosperm Floury Endosperm Germ Tip .

paint mfg plant schematic diagram

diagram acrylic emulsion manufacturing set up. How Paint is Made: Paint Ingredients and Manufacturing. Jun 27, 2019 The resin is the binder that holds all the pigments together It allows the product to adhere to the surface is it painted too A waterbased paint uses acrylic emulsion polymers to bind Common acrylic polymers come in a wide variety of types and combinations, such as methyl and ...

rotary ball mill schematics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1– times the shell diameter Figure .The feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 20–40 water by weight.

how to design a gold ball mill machine

31/08/2020 · GRINDING MILLS BALL MILLS New Used Mining Mineral Introduction to Milling Tools and Their Appliion. The ball mill is a key piece of equipment for grinding crushed materials and is widely used in production of powders such as cement silies refractory material and glass ceramics as well as for ore dressing of both ferrous and non ferrous metals Ball mills can grind wet or dry and can .

schematic diagrams for dry ball milling circuits

The process design of gold leaching and carbon in pulp Schematic Diagram Of Hydraulic Circuits WordPress. Single stage semi autogenous SAG or autogenous AG circuits and primary single stage SAG circuits followed by secondary ball milling After comminution the pulp is normally dilute andschematic diagram on the left is for load circuit diagram for ball mill using rtd sensor schematic diagrams ...

schematic of vibrating ball mill

the schematic of vibrating ball mill bestcoderindiagram ball mill and screening plant suttonseedsindiain. Ball mill Wikipedia the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser a simple process flow diagram of alumina mineral ball mill gold ball mill machine design ...

ONLINE SAG MILL PULSE MEASUREMENT AND OPTIMIZATION .

performance by investigating this signature's relation to mill product size, mill throughput, makeup ball size, mill speed, liner profile and ball addition rates. At the same time, it can also be used to design balls and liner systems that can survive longer in the mill.

crushing mill diagram | Mining Quarry Plant

19/03/2013 · ball mill maintenance, repair, installation, design,. kefid is a professional ball mill manufacturer. this blog is our ball mill blog, which will supply information . crusher to mill flow diagram,Crushing Process,Mining Process .

A Comparison of Manufacturing Technologies in the ...

Figure 1 presents schematic illustrations of a connecting rod and its ... Bellifortis (c. 1405), a hand mill operated by the crank and a connecting rod system. The ... () in his Treatise on Architecture compensated for the dead centers, where the flywheel had a .

Latest Posts

- الكرة في مطحنة الكرة

- الأبحاث المتعلقة ب تأثير محطم المحمولة منجم الذهب

- شراء الحزام الناقل companies in الهند

- إندونيسيا مصنع طاحونة السطح

- خطوات استخراج ومعالجة خام الحديد

- تأثير محطم الفك محطم ملموسة

- مصنع الأدوية الصغيرة تقرير المشروع

- المواصفات الفنية لي سحق المعدات

- اليابان تهتز مطحنة الكرة

- اختبار التعويم بلدية موسكو

- تصميم الفك محطم الفك دينامية درجة

- مزيج من كسارات الجليد

- مواد البناء سحق تأثير محطم

- كسارة الفك دليل الصيانة الكلي

- How To Remove Coating From Grinding Media Balls Of A Cement

- Abs Solvent Cementpressive Strength Resists Crushing Force

- Disadvantages Of Stone Quarry In Tamilnadu

- Mining Cable Specifications Greece

- Pengolahan Batu Kapur Pabrik Harga Mesir

- Crushed Stone Suppliers Stone Quarry Plant Portugal

- Graphite Mining Crushing

- Mill Loesche Mill Albania Hyderabad

- Syrup Grinding Mill Mule Drawn

- Heavy Duty Metal Pill Crusher

- Amonium Hydrogen Fluoride Crusher

- Stone Crusher Raw Material Calculation

- Fully Automatic Crusher Machine

- Ball Mill Company At Germany

- Mill Gold Ore Bergetar

- Solution Of Ghana Sand And Gravel Crusher Machine